Lisebelisuoa tsa Mechini ea Kaho le Likarolo

Ho aha lisebelisoa tsa Mechini le likarolo li etsa letoto la ts'ebetso ka tatellano ho fihlela sepheo sa ho qetela.

Ho itšetlehile ka mosebetsi oa eona, mechine ea kaho e ka aroloa ka lihlopha tse latelang tsa motheo: ho cheka, ho tsamaisa litsela, ho cheka, ho khanna liqubu, ho tiisa, ho rulela le ho qeta mechine, mechine e sebetsang ka konkreite le mechine ea ho etsa mosebetsi oa boitokisetso.

Likarolo tsohle li ka etsoa ho latela litšoantšo tsa hau tsa CAD le 3D kapa sampole.

Re tla u fa khotheishene ka nepo.

| Likarolo li kenyelletsa | CNC Machining Parts, CNC Milling Parts, CNC turning parts, Precision grinding parts, Milling parts, turning parts, Machined casting parts, Machined forging parts, castings, forgings. |

| Lintho tse bonahalang | Stainless steel, Alloy steel, Carbon steel, Cast steel, Cast iron, Aluminium alloy, Brass alloy, Plastic jj. |

| Kalafo | Ho thatafatsa carburization, ho thatafatsa linyeoe, Phekolo ea mocheso oa Vacuum, Ho thatafala le ho halefa. |

| Qetello ea bokaholimo | Ho roala zinki, ho roala ka Chrome, Phosphating, Electro-polishing, Electroless nickel plating. |

| Mochini o lekanyang | Mochini o lekanyang o hokahanyang, projector, tester ea roughness, hardness tester, concentricity tester, Height tester. |

| Ho paka | Linyeoe tsa lehong, lebokose kapa ka tlhokahalo. |

| OEM & ODM lia amoheloa. | |

Thepa e entsoeng ka mechine e etselitsoeng ho etsa mesebetsi ea kaho.Mechini e meng ea kaho e etsa letoto la mesebetsi ka tatellano ho fihlela sepheo sa ho qetela.Ho itšetlehile ka mosebetsi oa eona, mechine ea kaho e ka aroloa ka lihlopha tse latelang tsa motheo: ho cheka, ho tsamaisa litsela, ho cheka, ho khanna liqubu, ho tiisa, ho rulela le ho qeta mechine, mechine e sebetsang ka konkreite le mechine ea ho etsa mosebetsi oa boitokisetso.

Tiro ya go baakanyetsa e akaretsa go repisa mmu le go tlosa ditlhare, ditlhare le maje mo mafelong a a leng teng.E etsoa ke mechini ea kaho e kentsoeng holim'a chassis ea terekere ea crawler, joalo ka li-rippers, li-brashi cutters, le li-stump puller, tseo hangata li nang le lisebelisoa tse fapanyetsanoang, tse hlonngoeng tse loketseng mofuta oa mosebetsi o etsoang.

Mosebetsing oa mobu, mofuta oa mochine o sebelisoang o itšetlehile ka mofuta oa mobu o sebetsoang le mofuta oa mosebetsi.Mechini e sebelisitsoeng e kenyelletsa likharafu tsa mochini le li-excavator tse ngata, li-trench diggers, li-bucket loaders, le lisebelisoa tsa hydromechanization (bona EXCAVATING MACHINES).Lirolara tse sisinyehang le lirolara tsa litsela tse sa fetoheng tse nang le meqolo ea tšepe le lithaere tsa moea li sebelisoa ho kopanya lefatše ka har'a li-embankments le lisebelisoa tse betheng ea litsela.

Mechini ea ho epolla le mechini ea ho etsa mosebetsi oa boitokisetso e sebelisoa kahong ea litsela.Mechini e khethehileng ea litsela e sebelisoa ho lokisa libethe le bokaholimo bakeng sa litsela le mabala a lifofane.Mechini e tsamaisang literene e sebelisoa kahong ea seporo ho rala liporo le maqhama, ho tlatsa ballast le ho otlolla seporo.

Mefuta e fapaneng ea mechini e chekang e sebelisoa ha ho sebetsoa mobung o mafika, ho hula lisebelisoa tsa kaho tse se nang tšepe, ho tena mobu, ho beha liqubu, le ho beha liqoso tse phatlohang (seeDRILLING).

Mesebetsi ea ho khanna qubu bakeng sa ho kenya maoto le metheo e etsoa ka lisebelisoa tsa ho khanna qubu, tse kang lihamore tsa diesel, lihamore tsa mouoane le lisebelisoa tse thothomelang.Bakhanni ba liqubu tsa kaho ba phahamisa liqubu ebe ba tataisa lisebelisoa tsa ho khanna qubu nakong ea ts'ebetso.

Mosebetsi oa konkreite o etsoa ka mechine e khethehileng.Li-batchers le li-mixer tsa konkreite li lokisa motsoako oa konkreite, li-vibrators li kopanya konkreite, lipompo tsa konkreite li isa motsoako setšeng, 'me li-placers li amohela le ho aba motsoako.

Mosebetsi oa ho rulela o etsoa ka mechine ea ho rulela e hloekisang, e khutlisang morao, e lefang, le ho e manamisa lintho tse rulelang.Thepa e khethehileng, e fumanehang bohareng e fana ka mastic marulelong ka mor'a ho kopanya le ho futhumatsa.Lisebelisoa tse khethehileng li sebelisoa ho tlosa li-deposit tsa leqhoa ho tloha marulelong a marulelo.

Ha ho phetheloa mosebetsi, ho sebelisoa mechine bakeng sa ho boreleli samente, ho bentša litšoantšo tse entsoeng ka mosaic, parquet le ho penta, ho tlotsa putty le ho fafatsa pente.

Mefuta e meng ea thepa ea mechine e boetse e sebelisoa mosebetsing oa kaho, ho akarelletsa le likereene, mechine e phahamisang le e tsamaisang thepa (haholo-holo bakeng sa tšebetso ea kopano), e kenyang thepa le e laollang, e tsamaisang thepa, literaka, literekere, litsamaiso tse khōlō, litereilara bakeng sa mesebetsi ea lipalangoang le lisebelisoa tse fapaneng tsa motlakase.

Mekhoa e ka sehloohong ea ho ntlafatsa mechine ea kaho e kenyelletsa ho eketsa tekanyo ea matla ho boima ba 'mele le matla a ho jara thepa ea mochine ka bomong, ho hlahisa mefuta e mecha ea lisebelisoa tse fapanyetsanoang, ho qapa mechine e menyenyane (haholo-holo bakeng sa ho qeta ho sebetsa), ho hlahisa lisebelisoa tsa motlakase tse nang le mefuta e sa tšoaneng e feto-fetohang. lihokelo, le ho rala mechini e ipapisitseng le li-modular subassemblies le likarolo.Mokhoa oa ho qetela o hlahisa mechine ea kaho ea merero eohle e nang le lisebelisoa tsa lisebelisoa tse feto-fetohang tse nang le ts'epo e eketsehileng le bophelo bo bolelele ba tšebeletso.

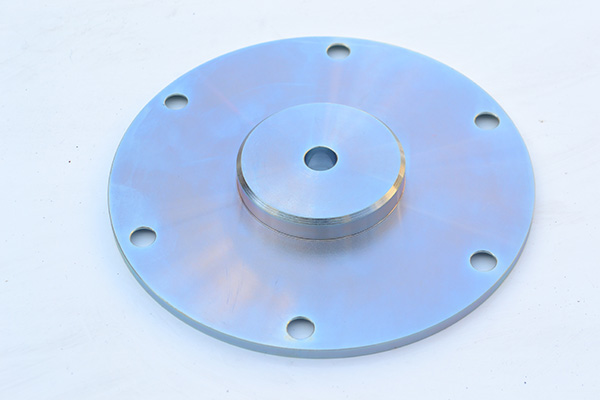

Likarolo tsa flange tsa tšepe ea carbon tse nang le plating

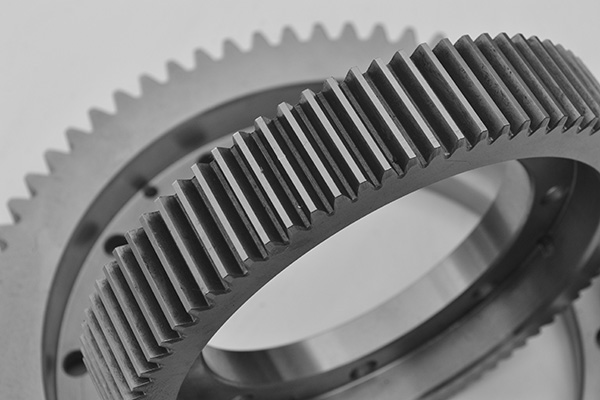

Likarolo tsa matlo a tšepe ea carbon ka kalafo

Likarolo tsa tšepe tsa carbon tse phahameng ka ho nepahala