Likarolo tsa koporo

Brass alloy ke motsoako oa koporo le zinki, ka litekanyo tse ka fapanyetsanoang ho fihlela thepa e fapaneng ea mochini, ea motlakase le ea lik'hemik'hale.Ke motsoako oa substitutional: liathomo tsa likarolo tse peli li ka nkela sebaka se seng ka har'a sebopeho se tšoanang sa kristale.

Koporo e tšoana le boronse, motsoako o mong o nang le koporo o sebelisang thini ho e-na le zinki.Bobeli boronse le koporo le tsona li ka kenyelletsa likarolo tse nyane tsa mefuta e mengata ea lintho tse ling tse kenyelletsang arsenic, lead, phosphorus, aluminium, manganese, le silicon.Ho ea ka nalane, phapang lipakeng tsa li-alloy tsena tse peli e ne e sa tsitsane ebile e hlakile, 'me tloaelo ea sejoale-joale ea limusiamo le thuto ea khale ea khale e qoba mantsoe a mabeli a lintho tsa nalane molemong oa "alloy ea koporo" e akaretsang.

Brass e 'nile ea e-ba thepa e ratoang bakeng sa mokhabiso ka lebaka la ponahalo ea eona e khanyang, e kang khauta;se sebedisoang bakeng sa ho hula dilai le dikonoko tsa mamati.E boetse e sebelisoa haholo ho etsa lisebelisoa ka lebaka la thepa e kang ho ba le sebaka se tlaase sa ho qhibiliha, ho sebetsa ka mokhoa o phahameng (ka bobeli ka lisebelisoa tsa matsoho le mechine ea morao-rao ea ho fetola le ho sila), ho tšoarella, le motlakase le mocheso oa mocheso.

Brass alloy e ntse e sebelisoa hangata lits'ebetsong moo ho hanyetsanang le kutu le khohlano e tlase e hlokahalang, joalo ka linotlolo, lihokelo, likere, li-bearings, casings tsa likulo, zippers, lipeipi tsa metsi, li-hose couplings, li-valve le li-plug le li-sockets tsa motlakase.E sebelisoa haholo bakeng sa liletsa tsa 'mino tse kang manaka le litloloko, hape e sebelisoa e le sebaka sa koporo ho etsa mabenyane a liaparo, mabenyane a feshene, le mabenyane a mang a etsisa.Sebopeho sa koporo, ka kakaretso 66% ea koporo le zinki ea 34%, e e etsa sebaka se setle sa mabenyane a koporo, kaha e bonts'a khanyetso e kholo ea ho bola.Brass e atisa ho sebelisoa maemong ao ho 'ona ho leng bohlokoa hore litlhase li se ke tsa thunngoa, tse kang li-fittings le lisebelisoa tse sebelisoang haufi le lintho tse tukang kapa tse qhomang.

| Sehlopha | Karolo ka boima ba 'mele (%) | Lintlha | |

| Koporo | Zinki | ||

| Alpha brasses | > 65 | <35 | Alpha brasses e bonolo, e ka sebetsoa ka mokhoa o batang, 'me e sebelisoa ho hatella, ho qhekella, kapa lits'ebetsong tse tšoanang.Li na le karolo e le 'ngoe feela, e nang le sebopeho sa kristale ea cubic e bohareng ba sefahleho.Ka karolo e phahameng ea koporo, li-brasses tsena li na le 'mala oa khauta ho feta tse ling.Karolo ea alpha ke tharollo e tiileng ea zinki ka koporo.E haufi ka thepa le koporo, e thata, e matla, 'me e batla e le thata ho e etsa mochini.Sebopeho se setle ka ho fetisisa ke 32% ea zinki.Likhopo tse khubelu tse hananang le ho bola, tse nang le zinki tse 15% kapa ka tlase, ke tsa mona. |

| Alpha-beta brasses | 55–65 | 35–45 | E boetse e bitsoali-duplex brasses, tsena li loketse mosebetsi o chesang.Li na le mekhahlelo ea α le β';β'-phase e hlophisitsoe ka li-cubic tse bohareng ba 'mele, ka liathomo tsa zinki bohareng ba li-cubes,' me e thata ebile e matla ho feta α.Li-alpha-beta brasses hangata li sebelisoa li chesa.Karolo e phahameng ea zinki e bolela hore likhoele tsena li khanya ho feta alpha brasses.Ho 45% ea zinki motsoako o na le matla a phahameng ka ho fetisisa. |

| Lisebelisoa tsa beta | 50–55 | 45–50 | Li-brasses tsa Beta li ka sebetsoa feela li chesa, 'me li thata, li matla,' me li loketse ho etsoa.Lintho tse phahameng tsa koporo tse tlaase tsa zinki li bolela hore tsena ke tse ling tsa likhahla tse khanyang ka ho fetisisa le tse nyenyane tsa khauta tse tloaelehileng. |

| Li-Gamma brasses | 33–39 | 61–67 | Ho boetse ho na le li-gamma brasses tsa Ag-Zn le Au-Zn, Ag 30–50%, Au 41%.Mokhahlelo oa gamma ke motsoako oa cubic-lattice intermetallic, Cu.5Zn8. |

| Koporo e tšoeu | <50 | > 50 | Tsena li brittle haholo bakeng sa tšebeliso e akaretsang.Lentsoe lena le ka boela la bolela mefuta e itseng ea lialloys tsa silevera tsa nickel hammoho le li-alloys tsa Cu-Zn-Sn tse nang le likarolo tse phahameng (hangata 40%+) ea tin le / kapa zinki, hammoho le li-alloys tse ngata tsa zinki tse nang le lisebelisoa tsa koporo.Tsena ha li na 'mala o mosehla ho hang,' me ho e-na le hoo li na le chebahalo ea silevera ho feta. |

Setšoantšo sa CuZn36Pb3

likarolo tsa shaft tse nang le gearing

CuZn39Pb1 koporo

ho sebetsa le ho kokota

CuZn39Pb2 koporo

likarolo bakeng sa valve

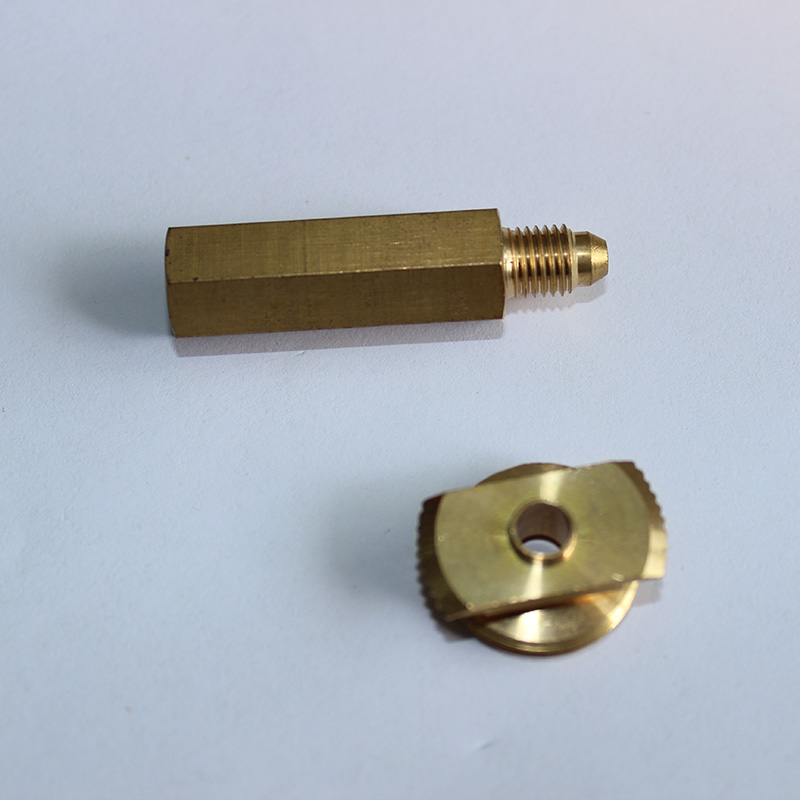

Hexgon koporo

likarolo tsa mochini

CuZn39Pb3 mochini oa koporo

le likarolo tsa ho sila

CuZn40 Brass

likarolo tsa molamu o retelehang

CuZn40Pb2 nate ea koporo

tšebeletso ea mochine

Ho nepahala ho phahameng

likarolo tsa koporo